Rozwiązania filtracyjne thoenes®

Rozwiązania filtracyjne thoenes® mogą być stosowane w różnych aplikacjach filtracyjnych. Ciągłość, precyzja, powtarzalność i przydatność do produkcji seryjnej charakteryzują nasze dziane filtry i tłumiki. Do produkcji używamy wysokowydajnych, najnowocześniejszych wielomateriałowych maszyn dziewiarskich. Montujemy produkt w naszej zrobotyzowanej komórce produkcyjnej przy użyciu niekończących się towarów.

Nasze rozwiązania filtracyjne mogą być precyzyjnie dostosowane do konkretnych wymagań aplikacji w naszej zrobotyzowanej komórce produkcyjnej. Możemy dostosować następujące parametry:

• Szerokość,

• Gęstość siatki,

• Skład materiału,

• Drobność włókna materiału podstawowego.

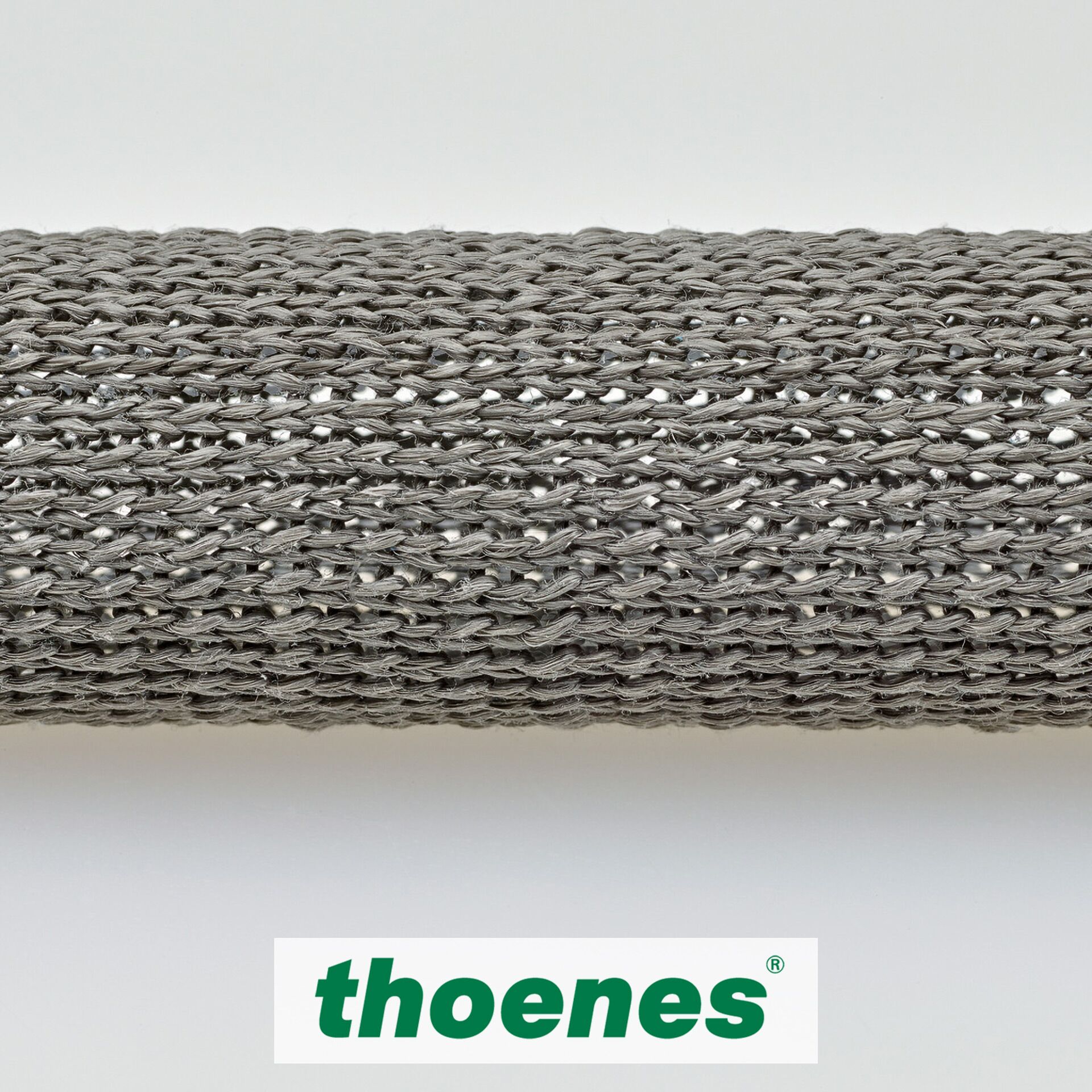

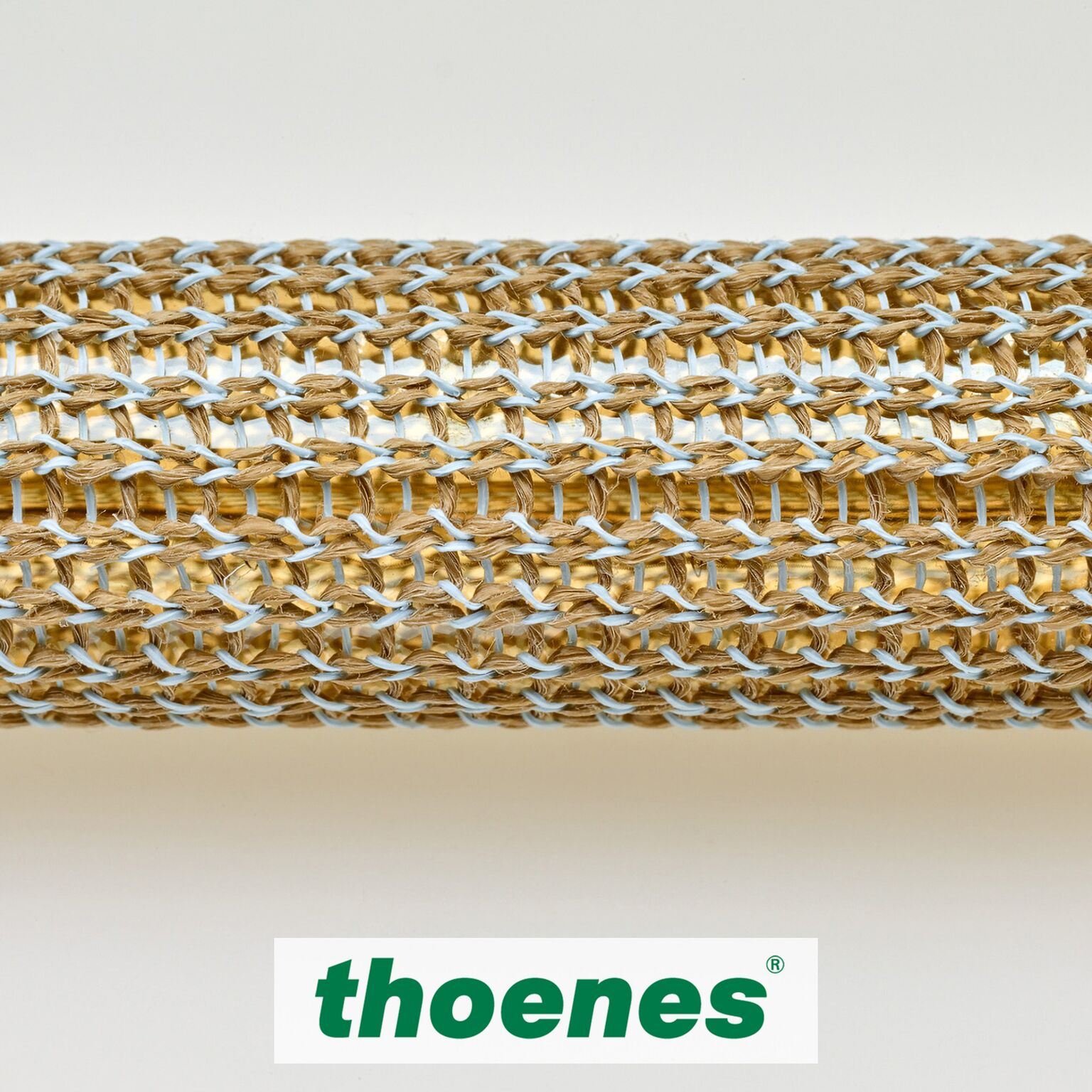

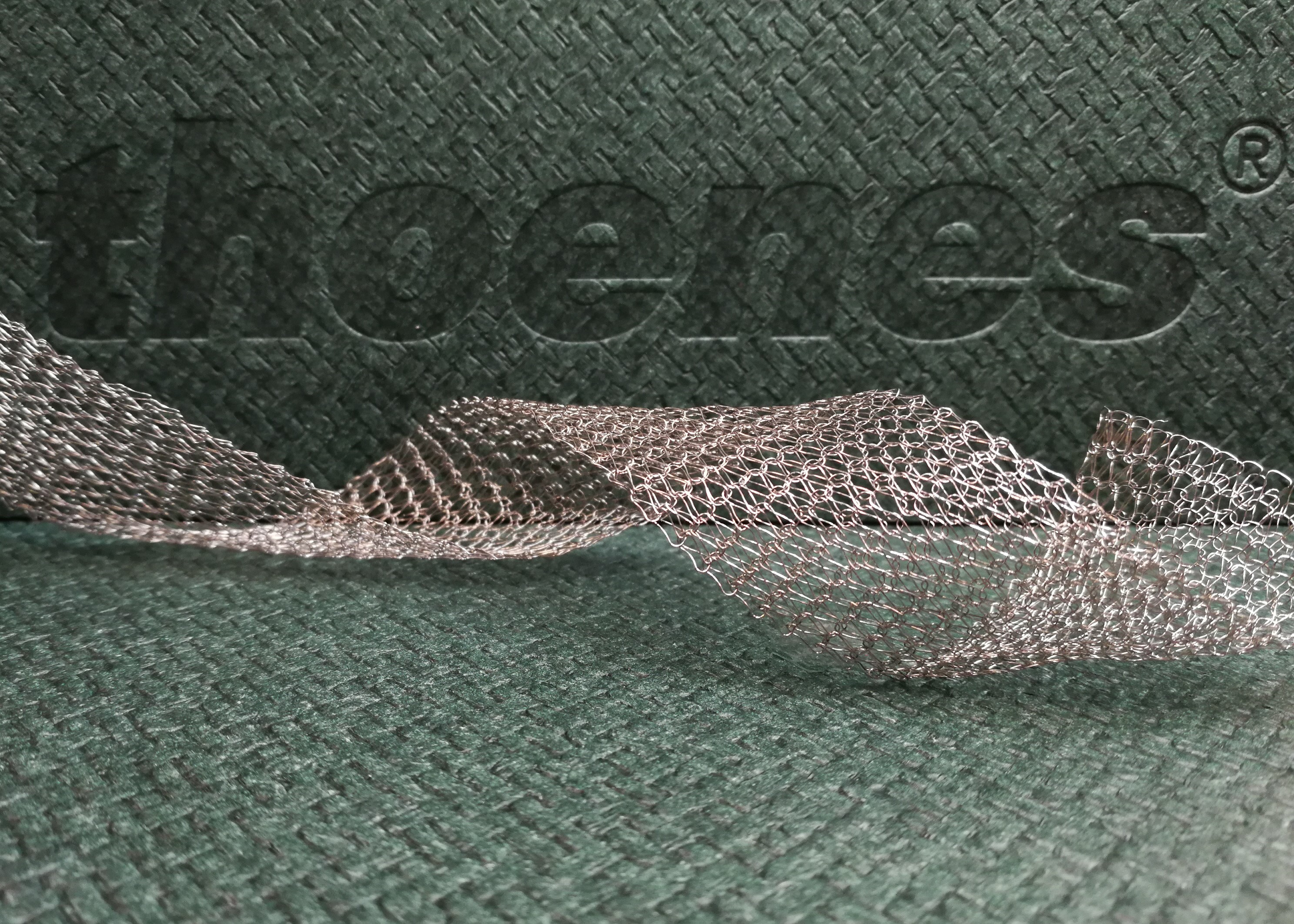

Oferujemy cienkie dzianiny, filtry i tłumiki, a także dzianiny metalowe. Dzianiny cienkie produkowane są na naszej maszynie dziewiarskiej. Jesteśmy w stanie wyprodukować bardzo cienkie i delikatne dzianiny z poliestru, nylonu, poliamidu, polipropylenu i innych materiałów. Zastosowany materiał, jego grubość i ustawiona liczba ściegów odgrywają decydującą rolę w produkcji pod względem elastyczności, wydłużenia, sztywności, sprężystości i porowatości cienkiej dzianiny. Dzięki wielu możliwym odmianom materiałów, zastosowaniu monofilamentów i multifilamentów lub ich kombinacji, nasze rozwiązania filtracyjne mogą służyć szerokiemu zakresowi zastosowań. Nasze siatki o drobnych oczkach mogą być stosowane na przykład w odpieniaczach basenowych, akwariach lub siatkach na węże o grubych oczkach. Filtry i tłumiki thoenes® mogą być stosowane w przemyśle motoryzacyjnym, przetwórczym i energetycznym. Mogą być stosowane w aplikacjach filtracyjnych (np. separacja materiałów w procesach chemicznych) lub jako tłumiki do określonej redukcji poziomu hałasu z określoną regulacją natężenia przepływu i czasu. Produkujemy metalowe siatki dziane jako elementy formowane lub dziane w szerokim zakresie wymiarów. Można stosować różne materiały bazowe - w zależności od rodzaju zastosowania i wymagań klienta. Dzięki swojej elastyczności i sprężystości dzianina może być wykorzystywana na wiele sposobów. Materiały takie jak drut chromowany, mosiądz, włókna szklane, przędze wysokotemperaturowe lub inne materiały, a także druty o grubości od 0,1 do 0,2 mm nadają się do dziania taśm i węży.